RS Ranger Build Guide

v1.9

Recommended PLA+, B Rig, 610g Bulb

These are the instructions for building the Racing Sparrow Ranger 695 3D printable rc yacht. The Ranger is designed for an excellent intro to RC sailing for the hobbyist or classroom.

Contents

- 1. Overview

- 2. Preparation

- 2.1. Decide Boat Specification

- 2.2. Tools Required

- 3. 3D Printing

- 3.1. Colour Batches / Filament Choice

- 3.2. Print the parts

- 4. Hull Build

- 4.1. Hull Preparation

- 4.2. Hull Anchor Disks

- 4.3. Hull Assembly

- 4.4. Hatch Opening

- 4.5. Rudder Control Rod

- 4.6. Rudder Cassette & Gudgeons

- 4.7. Sheet Exit Tube

- 4.8. Anchor Disk Sealing

- 5. Electrics

- 5.1. Servo Tray & Binding Receiver

- 5.2. Battery Box

- 5.3. Servo Tray Installation

- 5.4. Rudder Setup & Centering

- 5.5. Sail Arm Installation

- 5.6. Hatch Plate

- 6. Keel Build

- 6.1. Keel Halves Assembly

- 6.2. Join Bulb to Keel

- 6.3. Carbon Reinforcement

- 6.4. Bulb Filling

- 6.5. Final Keel Steps

- 7. Rudder Build

- 8. Rig, Mast & Boom

- 8.1. Cut Mast & Boom Sections

- 8.2. Mast Fittings

- 8.3. Mast Disk Installation

- 8.4. Joiner & Boom

- 8.5. Final Mast Components

- 9. Sail Construction

- 9.1. Workspace Setup

- 9.2. Sail Cutting

- 9.3. Sail Corners & Battens

- 9.4. Leading Edge Tape

- 9.5. Lacing Sail to Mast

- 9.6. Clew Adjustment System

- 9.7. Mainsheet Loop

- 10. Main Sheet & Radio Setup

- 10.1. Main Sheet Routing

- 10.2. Boom Angle & Trim

- 10.3. Radio Fine Tuning

- 11. Ready to Sail

- Printing Guide

1. Overview

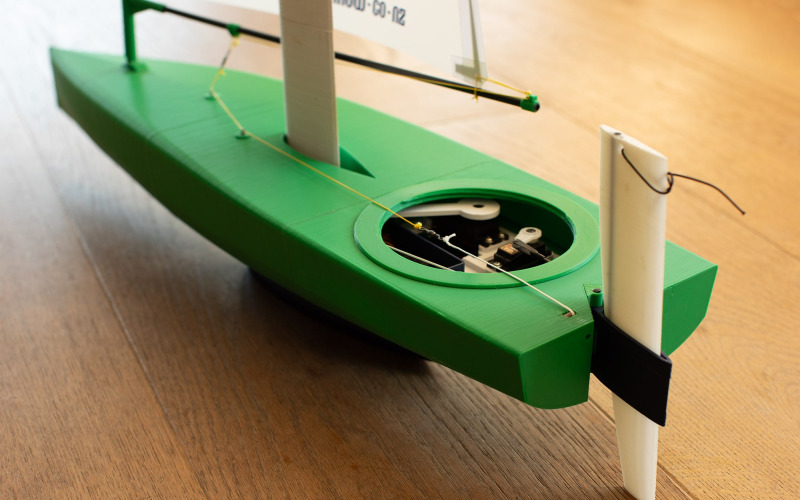

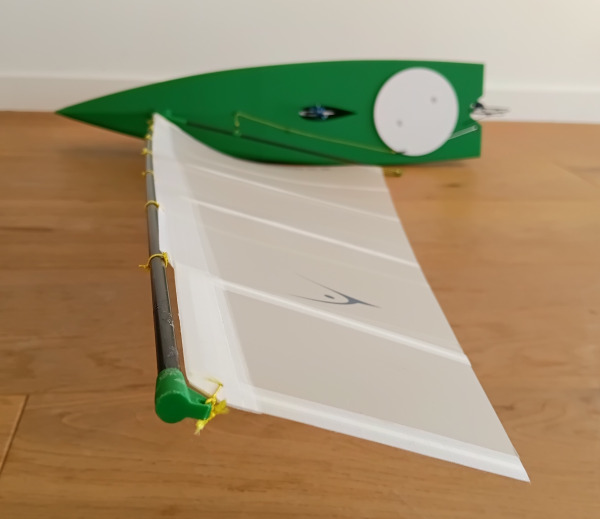

The RS-Ranger-695-3D is a 3D printed radio controlled yacht. By design it's the simplest boat build we offer at Racing Sparrow. This build is suitable for ages 10 and up.

For 3D printing advice and tips read our in-depth blog post.

2. Preparation

2.1. Decide Boat Specification

Before printing any of the boat parts it's a good idea to decide what size bulb and what size sail you are going to build. The 3D print files comes with 2 bulb weights, 530g & 610g. The sails come in sizes A, B, C.

When testing we found the overall best combination that sails well in a variety of breezes to be the 610g bulb and B size sail. This gives a wide range of sailing conditions for one set of appendages.

You can of-course build multiple keels and sails and interchange them for the conditions. Using a C sail with a 680g bulb allows the boat to sail in some very rough and sporty conditions!

2.2. Tools Required

These are the tools you will need to complete the build. None of these tools are mandatory, you may be able to do the job with what you have. This list makes the job easy.

- Craftknife

- Dremel

- Drill

- Small plyers

- Scissors

- Hammer, a small one is great

- Small round hobby file

- Needle

- Metal Ruler

- Sandpaper

- Marker Pen

3. 3D Printing

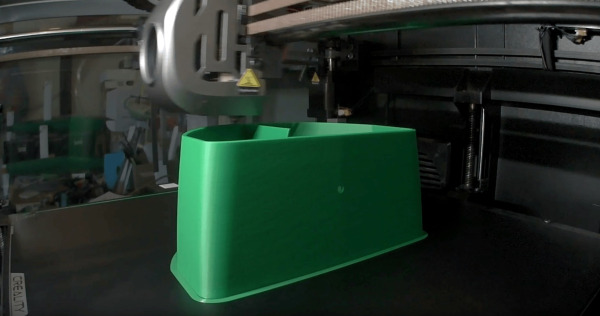

For this project the minimum printer bed size required is 200 x 200 x 200mm (xyz). This is within the capability of most mid-size hobby 3D printers.

3.1. Colour Batches / Filament Choice

Print part colours in batches, like green hull, white keel and rudder fins and dark blue components.

It really helps before you start to figure out the colour combos to save you extruding and retracting more than you need to.

At RacingSparrow we use mostly PLA+ to print all the parts but have also used standard PLA, clear PLAs, silk PLAs. All of these materials are great to use. We do find that PLA+ can withstand more punishment and is a little more heat resistant than other PLA's.

3.2. Print the parts

3d print all the parts. Use the checklist tab to see print settings for each part and keep track of progress.

4. Hull Build

4.1. Hull Preparation

-

A - RS Ranger - Hull Stern.stl

-

B - RS Ranger - Hull Mid.stl

-

C - RS Ranger - Hull Foredeck.stl

-

D - RS Ranger - Hull Bow.stl

-

E - RS Ranger - Hull Nose Cap.stl

-

Masking Tape

Clean up the printed parts carefully, mainly around the joins with sandpaper, craft knife, and file.

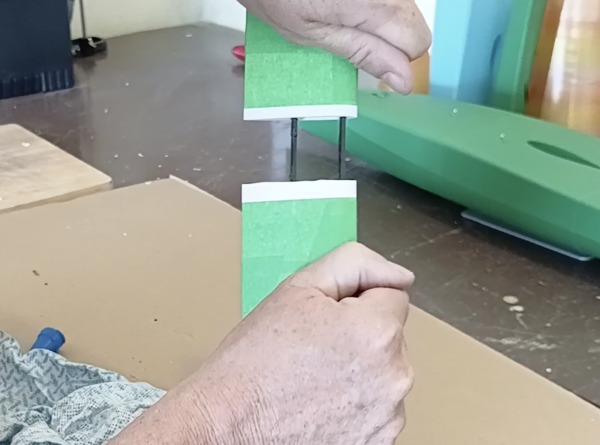

Masking Tape the hull joins on both sides of the joins so when you glue them together you don't get glue over-run at the joins.

4.2. Hull Anchor Disks

-

B - RS Ranger - Hull Mid.stl

-

C - RS Ranger - Hull Foredeck.stl

-

H - RS Ranger - Anchors + Washers x 2.stl

-

(CA Glue) Superglue 20g

-

Split pins (25mm x 3.5) x 2

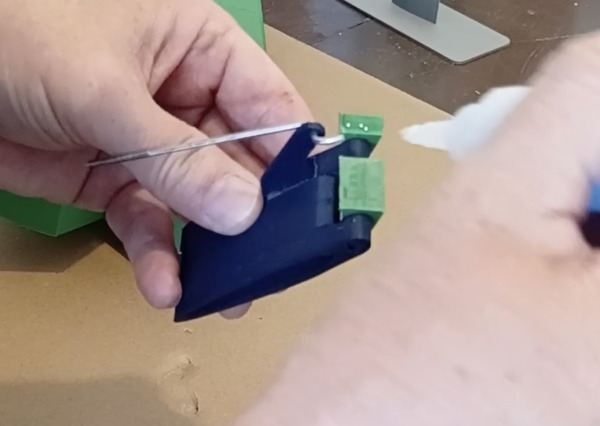

Build two sheet anchors by bending a split pin with pliers around the printed part.

Tape around the holes to stop finger marks then glue the anchors from inside the hull with superglue. Make the loops front-facing.

4.3. Hull Assembly

-

A - RS Ranger - Hull Stern.stl

-

B - RS Ranger - Hull Mid.stl

-

C - RS Ranger - Hull Foredeck.stl

-

D - RS Ranger - Hull Bow.stl

-

E - RS Ranger - Hull Nose Cap.stl

-

(CA Glue) Superglue 20g

Super glue the hull together starting from the back of the boat and work forwards. Use plenty of glue to ensure the joins are water tight.

Now that the boat is now one piece and while the tape is still on the hull, run a bead of superglue along each join, then quickly wipe away the excess with a clean rag. This will seep into the gap and weld the joins together.

Remove the tape straight away before the glue sets completely.

4.4. Hatch Opening

-

P - RS Ranger - Hatch Plate.stl

Use a marker pen and complete the circle where to cut the hatch supports.

With a Dremel disk or cutting tool, cut off the print supports. A Dremel sanding disk is a great way to clean up the cuts. Test place the hatch plate multiple times and keep tidying the hole until it sits flat.

Set aside the hatch plate for now, we'll glue that down further along the build process.

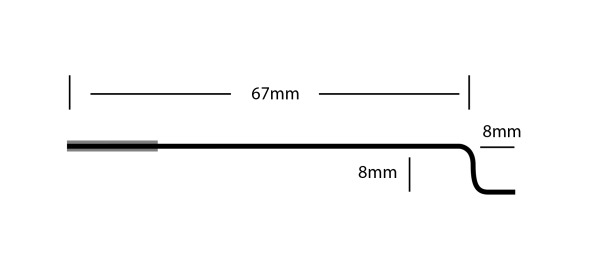

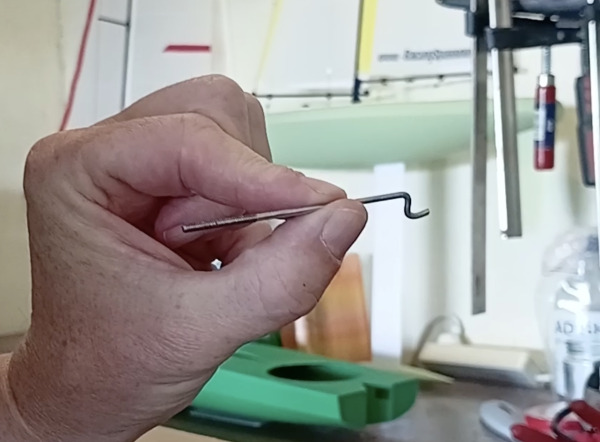

4.5. Rudder Control Rod

-

Rudder Control Rod & Clevis

Note the measurements needed for the push rod. Bend this into shape with a pair of pliers.

The threaded part will end up attached to the servo control arm inside the boat.

4.6. Rudder Cassette & Gudgeons

-

F - RS Ranger - Gudgeon Bottom.stl

-

G - RS Ranger - Gudgeon Top.stl

-

I - RS Ranger - Rudder Cassette Bottom.stl

-

J - RS Ranger - Rudder Cassette Top.stl

-

(CA Glue) Superglue 20g

-

Carbon Rod Round 4mm - (50mm length)

-

Rudder Control Rod & Clevis

Using the rudder as a guide rail inside the two cassette halves, super glue together the cassette. Keep sliding the rudder slightly so it does not glue in place.

Cut the 4mm carbon rod for the rudder connection. It needs to be 42mm long. Sand the ends flat with slightly bevelled edges.

Attach the rudder cassette and gudgeons by tapping the carbon rod through the holes. The fit should be snug but removable. You may need to drill and/or file the holes to get the fit just right.

Attach the Z-bend rod to the rudder cassette. You need to glue the rudder cassette in place with the z-bend pre-attached. It's much harder to do afterwards. You may need to twist the thread end through the out hole first before gluing, it's quite a snug fit.

Glue the gudgeons in place with superglue whilst being attached to the cassette. This is the easiest way to make sure the holes and carbon are aligned correctly. Top gudgeon flush with deck. Avoid gluing the cassette. Rotate the rudder after a few seconds to confirm free movement. Press firm as the glue sets for 20 seconds.

4.7. Sheet Exit Tube

-

A - RS Ranger - Hull Stern.stl

-

(CA Glue) Superglue 20g

-

Brass Tube 1/8

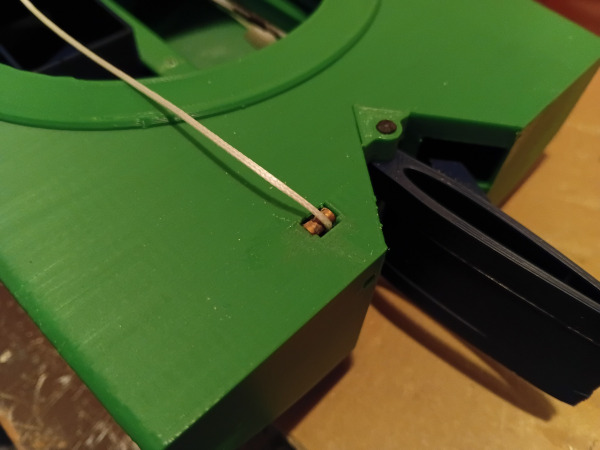

First break off the print in place support triangle covering the hole and clean up the edges with a craftknife and/or file. Mark the brass tube length against the exit hole with a marker pen.

Cut slightly oversize with a Dremel then file the ends until there is a snug press fit. Glue with small drops of superglue in each seat in the PLA+.

4.8. Anchor Disk Sealing

-

H - RS Ranger - Anchors + Washers x 2.stl

-

Masking Tape

-

Epoxy Resin 150ml

Mix a small amount of epoxy resin. Make sure to mix/stir well. Seal around both split pins using a small off-cut of metal and dabb on the epoxy.

Add a printed washer to create a waterproof seal. Masking tape helps prevent finger marks around the surrounded hull area where your fingers will press against the outer hull skin.

Once the epoxy sets you will have a waterproof and solid lead for the braid lines to run through.

5. Electrics

5.1. Servo Tray & Binding Receiver

-

L - RS Ranger - Servo Tray.stl

-

RadioMaster Pocket Controller

-

RadioMaster R86 Receiver

-

Sail Servo S3003

-

Rudder Servo

-

Power Switch On/Off

-

Small 3mm screws x 2

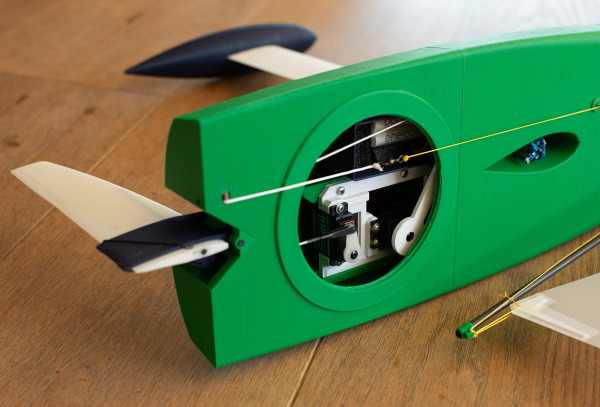

Screw in place the on/off switch.

Screw servos onto the servo tray. Use just the screws the servos come with and no rubber feet or ferrules needed.

While the servos and wires are outside the boat is the best time to bind the transmitter to the receiver and program the input channels. This will be quite specific to the brand of gear you have.

To put the receiver in bind mode press the small button on the receiver and at the same time switch the on button and give the receiver power. A red light will then flash.

Search youtube and google for relevant information on how to bind and program your transmitter. I find on my RadioMaster Pocket that channel 1 is rudder and channel 3 is the sail arm by default. I plug the battery switch into channel 5 or 6.

The battery compartment fits 4xAA or the preferred lighter weight 4xAAA packs. If using AAA pack batteries with some scraps of foam in the battery casing so they are snug and won't bounce around when sailing.

Note: there is a STEP file for the servo tray so you can adjust the 3d model to your specs if the servos you have are a different size. You can open a STEP file in a program like Fusion360 to re-create a new STL file.

5.2. Battery Box

-

M - RS Ranger - Battery Box.stl

-

N - RS Ranger - Battery Box Lid.stl

-

(CA Glue) Superglue 20g

Glue the battery box lid to the battery box, then glue the battery box into the hull seat. It is designed to keep the weight as far forward as possible.

5.3. Servo Tray Installation

-

Small 3mm screws x 2

Install the servo tray and route the wires into the battery box. Screw the servo tray into the hull with the two 3mm screws.

5.4. Rudder Setup & Centering

-

Rudder Control Rod & Clevis

With the electrics switched on and the servos responding to the transmitter centre the rudder servo. Screw the clevis in or out to get the exact length required. You need a single arm standard size servo horn. You can cut off any part that is not needed with a Dremel. The rudder cassette needs to be centred as best as possible. You may find the push rod sticks in the outlet hole in the hull. Bike chain lube is a great way to let this slide smoothly.

You can also fine tune this from the controller trim buttons. Once happy and all trimmed and correct screw the servo arm to the servo. Try not to over tighten the screw, it’s easy to do and can easily strip the thread in small servos.

5.5. Sail Arm Installation

-

N2 - RS Ranger - Sail Arm.stl

-

(CA Glue) Superglue 20g

For the sail arm glue a round servo horn to the underside of the printed sail arm using superglue. It welds the two together and is very strong. Make sure to glue it centred. The top side needs to be accessible for the servo screw.

Like you did with the rudder servo switch on the electrics and this time set the transmitter to where you have the sails pulled all the way in. Attached the arm so it’s just about touching the keel centre case. The servo should throw the arm 90 degrees giving the perfect amount of travel for the boom.

The arm should travel only 4mm above the battery case. It’s a tight squeeze but if everything is straight and built tight it will sit just in the right space when the arm turns.

5.6. Hatch Plate

-

P - RS Ranger - Hatch Plate.stl

-

(CA Glue) Superglue 20g

Test fit the hatch plate and ensure nothing is rubbing when the arm turns.

When happy apply plenty of super glue to the underside of the plate and glue it to the deck whilst applying moderate pressure for 20 seconds.

Make sure to line up the indent hole with the centreline of the boat.

6. Keel Build

6.1. Keel Halves Assembly

-

S - RS Ranger - Keel Half.stl x 2

-

Masking Tape

-

(CA Glue) Superglue 20g

-

Carbon Rod Round 3mm - 250mm length

Using masking tape cover the keel completely with tape to stop glues and hand marks while you build. Make sure you leave the end clear of tape so it can glue into the bulb slot.

Cut 2 lengths of 3mm Carbon rod to 75mm in length. Clean up the ends up with sandpaper. Super glue the keel together with the 2 rods.

6.2. Join Bulb to Keel

-

Bulb 610 Main.stl

-

(CA Glue) Superglue 20g

Prepare the keel to fit neatly into the bulb trench then super glue in place.

6.3. Carbon Reinforcement

-

Carbon Square Rod 4mm - 345mm lengths x 4

-

Epoxy Resin 150ml

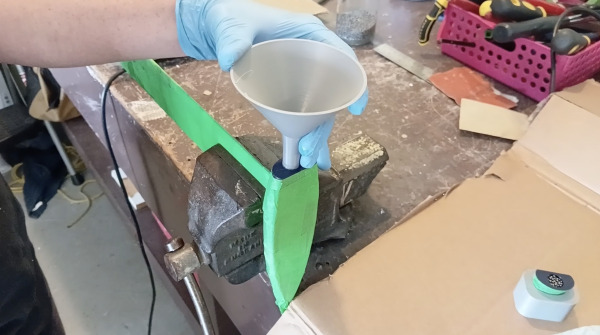

Prepare an area for gluing the carbon square 4mm rods into the keel. An old scrap of cardboard box is an ideal way to do this. This is going to get messy. Wearing gloves mix some epoxy resin. You need to mix enough to completely coat all 4 rods on all sides.

Do this with your hands whilst wearing the gloves. Slide the 4 rods into the keel trench so they go all the way to the bottom; right through to the base of the bulb. You may need to tap them in place with a hammer.

I find it a useful to switch to a fresh set of gloves part way through so you don’t cover your tools in glue. Leave the keel sitting upright whilst drying to prevent unwanted curvature.

6.4. Bulb Filling

-

Epoxy Resin 150ml

-

Methylated Spirits

-

Lead Shot 540g (Larger bulb)

Place keel upright with bulb nose supported.

Fill bulb with lead shot leaving 1cm gap. Use the printed funnel to assist in the pouring of the both the lead and the resin. Note that the 610G bulb actually has only 530-540g of lead shot inside. The rest of the weight is made up by the carbon rod, the PLA+ shell and the resin filling.

Pre the area for resin drips, cardboard underneath and a rag to mop up an drips or excess resin. A change of gloves part way through can be a good idea.

Mix 50ml resin thoroughly, then add 15ml mineral turpentine and mix again. No slowly pour resin in via the funnel allowing it to soak through lead shot. It's a slow process that requires some patience.

Tap bulb to release air bubbles. Top up with lead and resin so that it goes all the way to top of each part.

Leave these to sit for around 12 hours or until completely set.

6.5. Final Keel Steps

-

T - RS Ranger - Bulb Join Key.stl

-

(CA Glue) Superglue 20g

-

Spectra Rope 150mm

Once set, glue join key disk and nose.

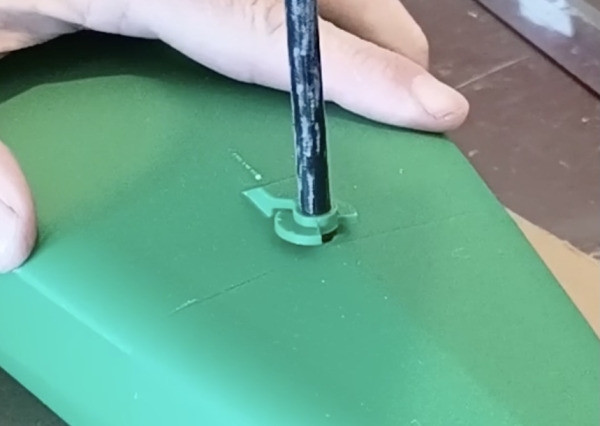

Drill 4mm hole at top of keel for rope loop.

7. Rudder Build

-

K - RS Ranger - Rudder Blade.stl

-

(CA Glue) Superglue 20g

-

Carbon Rod Round 3mm - 250mm length

Remove the mouse ears if needed with a craftknife.

Cut 105mm length of 3mm carbon rod.

Mask the top of rudder with masking tape to prevent finger marks. Glue rod in place using superglue, tapping gently if needed.

Trim flush once set with a file or Dremel.

Cut a length of bungy or use a rubber band and create a loop retainer and tie through the rudder top hole.

8. Rig, Mast & Boom

8.1. Cut Mast & Boom Sections

-

Carbon Mast 6mm x 4mm-inner diameter - 1000mm length

-

Carbon Boom 5mm - 360mm length

Choose which rig you are making and cut the 6mm mast and 5mm boom to the plan dimensions found in the sail plans tab.

We recommend the B-rig as an excellent all-rounder for a wide range of wind conditions.

If you are really keen you can always build multiple rigs and bulb sizes to get the most out of your Ranger! The sails and bulbs are easily inter-changeable on the go when sailing.

8.2. Mast Fittings

-

U - RS Ranger - Mast Disk.stl

-

V - RS Ranger - Rig Spar Joiner.stl

-

W - RS Ranger - Boom Attachments x 2.stl

-

X - RS Ranger - Mast Top.stl

Test fit all fittings. Lightly sand the carbon where the fittings glue so the parts have a good bond to the carbon.

8.3. Mast Disk Installation

-

U - RS Ranger - Mast Disk.stl

-

V - RS Ranger - Rig Spar Joiner.stl

-

(CA Glue) Superglue 20g

-

Carbon Mast 6mm x 4mm-inner diameter - 1000mm length

Slide the joiner up the mast and out of the way in preparation for the next part.

Insert the mast into hull, position the disk so the mast spins freely but cannot lift out. Once happy with the disk placement gently remove the mast from the hull and glue the disk by running superglue around the top and bottom. The glue will seep into the gaps and bond it.

Wipe away any excess glue and let the glue dry.

8.4. Joiner & Boom

-

V - RS Ranger - Rig Spar Joiner.stl

-

(CA Glue) Superglue 20g

-

Carbon Mast 6mm x 4mm-inner diameter - 1000mm length

-

Carbon Boom 5mm - 360mm length

Add plenty of glue to where the joiner will sit and quickly slide the joiner in place before the superglue takes hold. You only get one chance so practice first and prep well. Measure twice, glue once!

Now glue the joiner against disk with the disc notch facing forward.

Lightly sand the boom end and glue the carbon boom into the joiner.

8.5. Final Mast Components

-

W - RS Ranger - Boom Attachments x 2.stl

-

X - RS Ranger - Mast Top.stl

-

(CA Glue) Superglue 20g

-

Carbon Mast 6mm x 4mm-inner diameter - 1000mm length

-

Carbon Boom 5mm - 360mm length

Position and glue the boom attachment points as per the sail plans.

Glue the topper attachment making sure it is aligned with the boom.

9. Sail Construction

9.1. Workspace Setup

Use a flat, cuttable surface such as scrap vinyl, plywood or cardboard.

9.2. Sail Cutting

-

Mylar Sail Material 883 x 347mm rectangle (A rig)

The sail is ideally made from one piece of material. No seams are needed unless your material you are using comes in smaller pieces like A4 architectural drafting film. You can use many things for sail material. Drafting film, reflective grow mylar, ripstop nylon, spinnaker sail offcuts, floral mylar. If you need to; first join panels of material to form one large rectangle as per the sail plans.

Cut the sail rectangle from your one piece material using the plan dimensions.

Measure, mark then cut the mast and boom offsets according to the sail plans.

Measure, mark then cut the square top measurement down to the bottom corner to complete the final outer shape of the sail.

9.3. Sail Corners & Battens

-

B Rig - RS Ranger - Batten Set.stl

-

B Rig - RS Ranger - Sail Corners.stl

-

Spinnaker Repair Tape - half roll

Tape the 3D printed corners in place using spinnaker tape. The tape should go well past the sail edges. Next you will trim these edges off with a craftknife.

Install the sail battens using tape strips. Find placement measurements on the sail plans.

Make sure to use the correct size battens from the STL fileset. Each set have some slight variations specific to each sail size.

9.4. Leading Edge Tape

-

Spinnaker Repair Tape - half roll

Apply sail tape to both sides of the leading edge stretching the sail while taping.

For this step it really helps if someone helps you to stretch the sail as you apply the tape. This will reduce any unwanted wrinkles.

Trim the tape to leave a 5mm double thickness leading edge and flush edges.

At the top of the sail cut a notch in the tape down to the second square batten. That part gets in the way of the mast and disturbs the sail shape.

9.5. Lacing Sail to Mast

-

(CA Glue) Superglue 20g

-

Braid Line - 1 meter

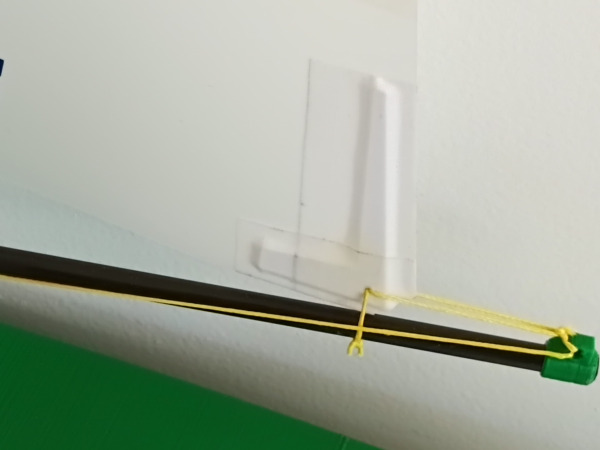

Starting at the top of the sail stitch the sail with a needle loaded with braid line. Instead of threading each loop and attachment point one at a time, it’s much easier to do this with one continuous length of braid meaning you only need to thread the needle with braid once.

Start at the top through the eyelet then every 100mm pop the needle through the leading edge sail tape. Work your way down the sail. Once down to the sail tack move across to the clew. As you do this you will need to keep threading more braid through the existing holes you have made.

Now that you’ve got thread running through all holes you can remove the needle from the thread and starting at the top cut the braid into 200mm lengths.

The clew will need a longer 300mm piece of rope loop. Now tie each loop with a simple reef knot attaching a small loop to the sail with 2 x 100mm tails.

Again starting at the top of the sail, tie the top line to the mast topper making it snug and as close to hole as you can. Then working down the mast tie each loop around the mast and loosely tie each attachment point. You don’t want them to be tight against the mast. You want them slightly loose so they can freely move around the mast and the sail will naturally form the correct shape governed by the sail battens.

When you get down to the tack you want to tie this so the front luff of the sail holds some tension.

For the clew it will attach in two places. The first attachment is a snug fit to the boom. The second will be the adjustable outhaul covered in the next step.

After this step superglue all the knots on the back of the mast with a small dot of superglue. This will make the knots permanent and is a great trick to reduce breakages whilst sailing. Once the glue has set trim all knot ends close to the knot with a sharp craft knife.

When this step is complete you should notice both the mast and boom have slight bends in them. The bend is great as it keep the sail tight and in the correct shape.

9.6. Clew Adjustment System

-

W2 - RS Ranger - Bowsie.stl

-

(CA Glue) Superglue 20g

-

Braid Line - 1 meter

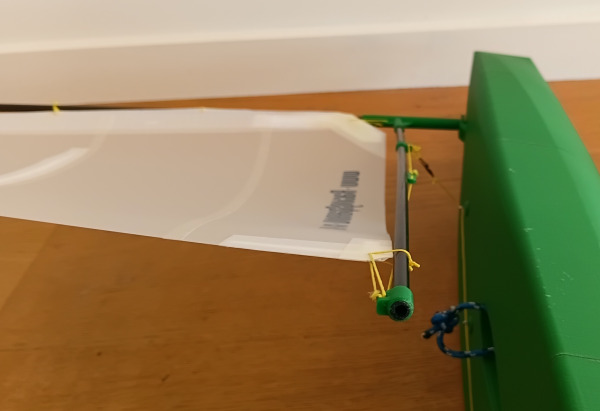

For the clew you want to create an adjustable braid line using a bowsie. See the diagram for how this is tied. The clew line will start by being tied to the end boom fitting then up through the sail eyelet. It then goes back through the end boom fitting and runs forward. It then goes through 2 holes in the bowtie, through the mid boom fitting then doubles back to finish up tied again to the bowsie. The bowsie adjuster is just like a tent guy rope setup.

You want the adjustment to be able to flatten the sail completely or have it so the foot of the sail has some loose slack of about 2cm at most at the widest point of the sail.

9.7. Mainsheet Loop

-

(CA Glue) Superglue 20g

-

Braid Line - 1 meter

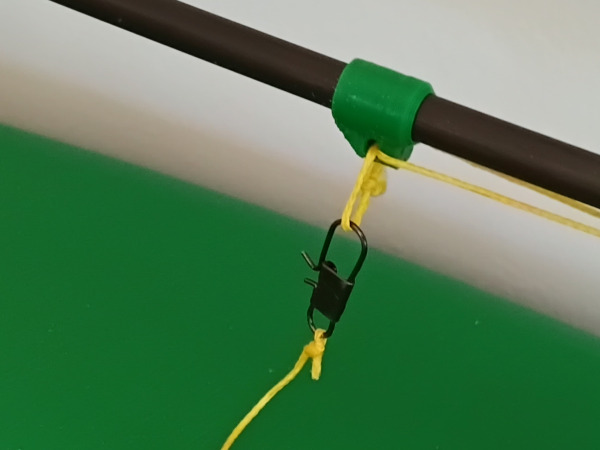

Add a mainsheet loop to boom attachment. This is used to attach the fishing clip to when sailing. The loop needs enough room so you can easily pop a clip on just before sailing. It does not need to be tight or keep the clip too close to the boom.

Tie your knot then seal with a drop of superglue. It's quite critical that this knot does not come undone!

10. Main Sheet & Radio Setup

10.1. Main Sheet Routing

-

(CA Glue) Superglue 20g

-

Braid Line - 1 meter

-

Fishing Clip & Swivel

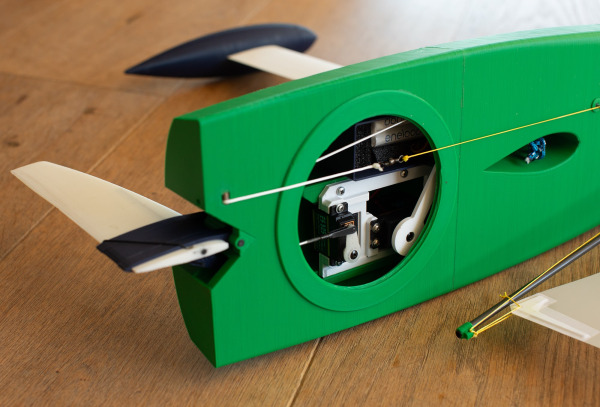

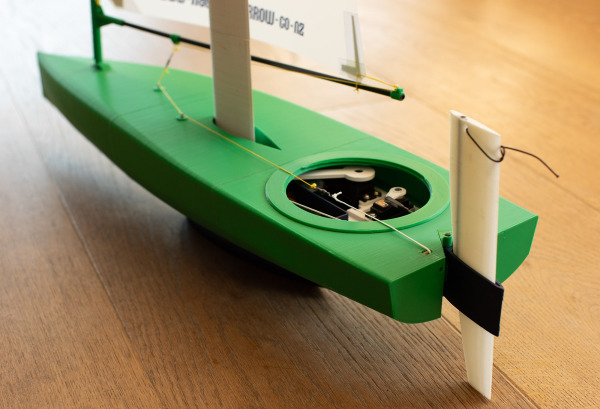

Tie a braid line to the sail arm. You can do this outside the boat then pop the arm back on the servo.

Run the line from the sail arm out the back of the boat then around the copper tube, through anchor eyelets, to fishing clip via swivel.

Glue all the knots with super glue.

10.2. Boom Angle & Trim

The boom should point toward each back corner of the boat when sheeted in.

When sailing upwind the mistake many people make is having the boom centred. While this is how you would set a 2 sail boat, on a single sail boat you need a different setup.

Downwind the boom travel should reach just beyond 90 degrees. This is great for learning to sail by the lee. Watch that youtube video to learn more.

10.3. Radio Fine Tuning

Fine tune the sail trim via the transmitter trim buttons. You should only need a little bit of trim ideally.

Another excellent improvement to the handling of your boat is to add exponential to the rudder for fine control and reduced drag. Adding expo means the rudder makes more subtle movements. The RS Ranger is very well balanced by design and does not need large rudder corrections.

Remember every time the rudder is corrected it acts as a break and slows you down. Minimising rudder movement is key to sailing faster!

11. Ready to Sail

-

(CA Glue) Superglue 20g

-

Braid Line - 1 meter

The boat is now ready to sail.

Before sailing, test the hull in a bath or tub to check for leaks. On the first sail, run the boat for about 30 seconds, return to shore, and inspect inside. You may need to add a little superglue to any joins or gaps you missed.

The stern includes a small drain hole. Leave this open initially to make draining easy if leaks are present. Once you’re confident the boat is watertight, seal the hole with a small dab of resin to prevent water ingress in rough conditions. This is usually only necessary in choppy or open water.

When sailing, take a sponge, spare braid, and superglue; water finds its way in, and knots can come undone.

When built correctly, the boat remains very dry inside. The internal layout also lifts the electrics above any water, keeping the battery and receiver protected in their own compartment.

Printing Guide

The Racing Sparrow 3D boats are designed to be printed from PLA+. One roll of filament should be enough to print the hull parts, keel, bulb, rudder, and rig parts. The 3d model has been designed so that no part is too large making this easily printable on most home 3d printers. Minimum Printer Bed Size Required: 200×200×200mm (XYZ).

Simply load the STL files into the slicer software and start printing. All parts are pre-oriented correctly so you should not need to rotate.

For 3D printing advice and tips read our in-depth blog post.

The settings the author used on a Creality K1 Max Printer were:

PLA+ eSun

Nozzle 0.4,

Wall count of 2: top 4, bottom 4 layers

Use mouse ear for problematic lifting edges

210°C Nozzle

60°C Bed

34°C Enclosure

Either 18% infill or 100% depending on the part

300mm/s speed

Carbon Fibre

Before gluing any carbon it’s best to sand off the glossy outer coating of the spar. These coatings are just thin layers added to the carbon by manufacturers. When gluing this will add much better bond of carbon and PLA+. It’s easiest to sand these with a dremel or it can be done by hand with sand paper. Wear gloves to avoid itchy hands from the cut carbon particles. Carbon glues well with both CA and epoxy glues.