3D Printed RS1000

Our most powerful model, but so easy to make.

Materials & Build Instructions

Key design features:

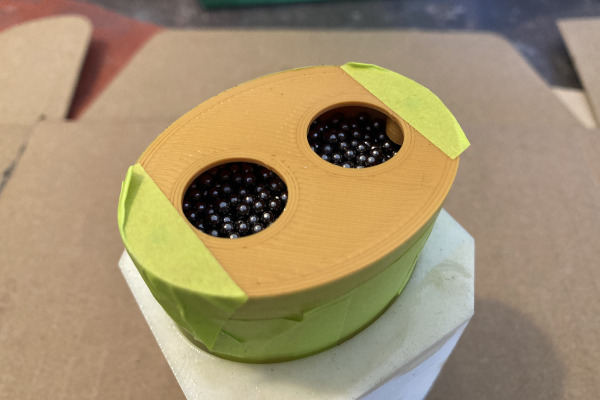

1000mm length, 200mm width, 1250mm mast, 2Kg bulb

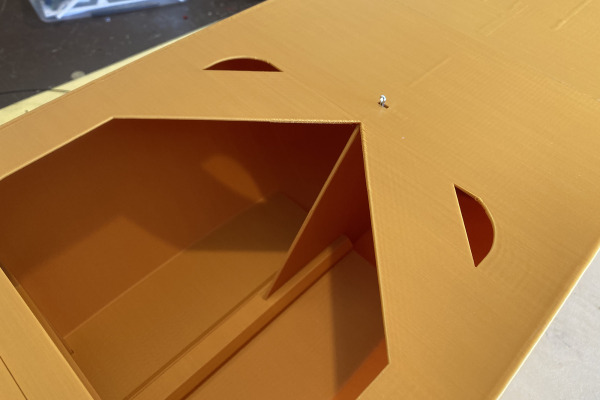

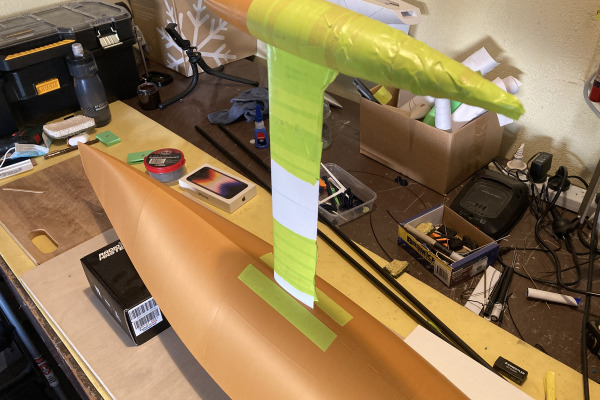

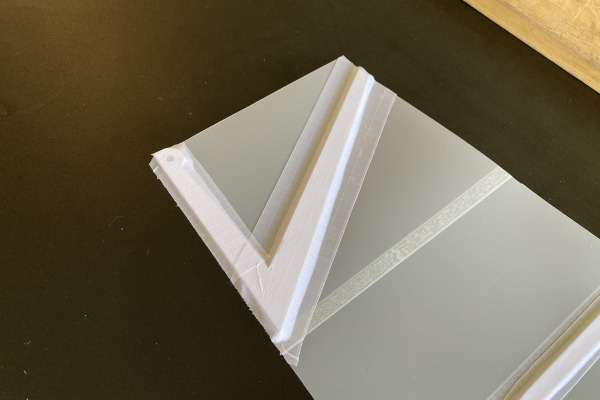

- Hull printed in 4 parts

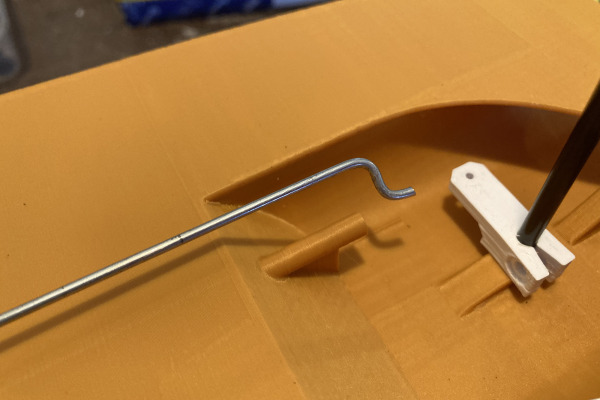

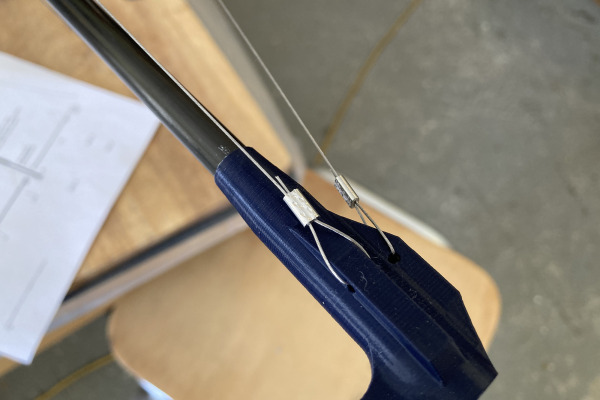

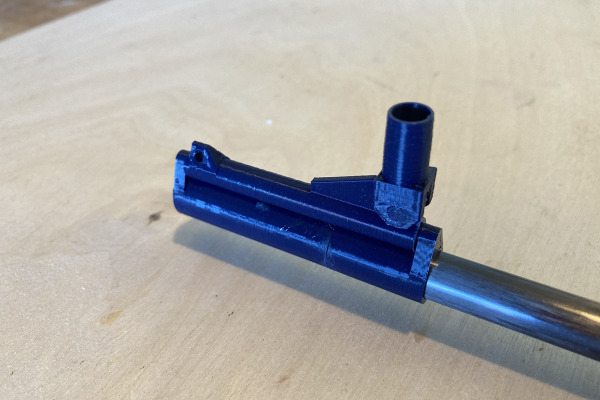

- Printed rig fittings

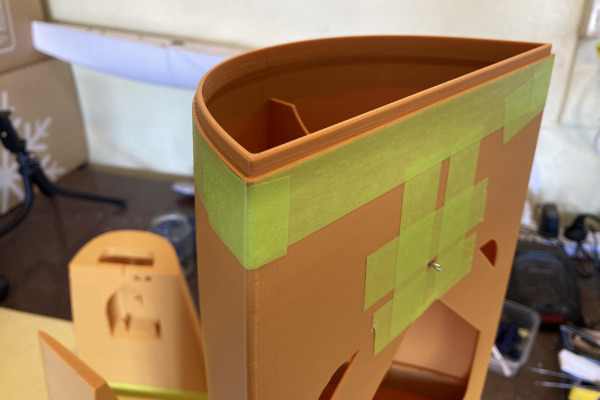

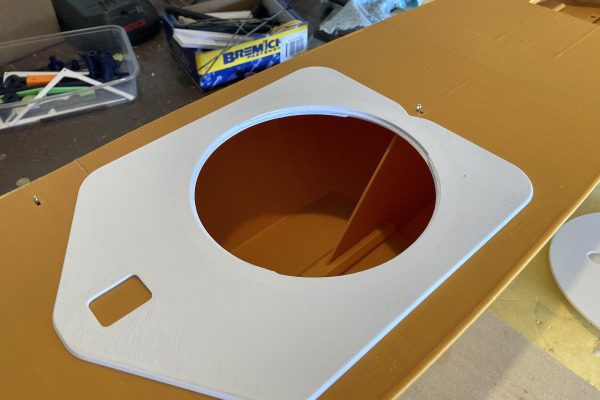

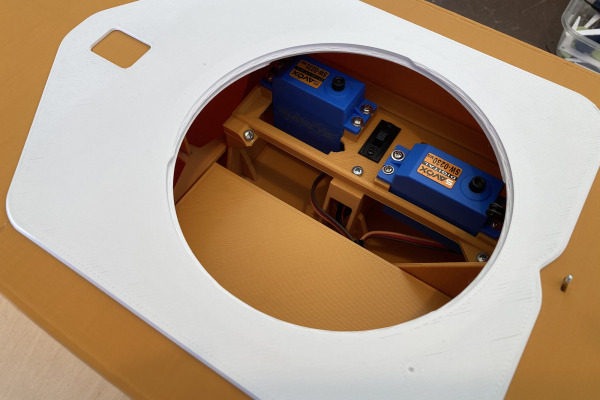

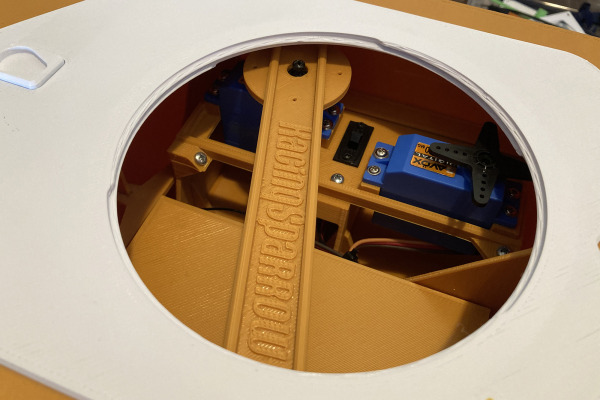

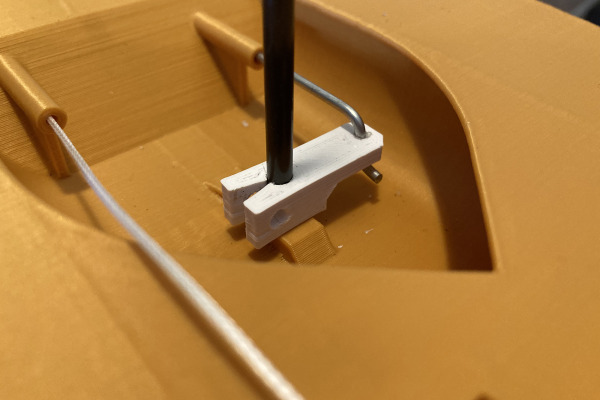

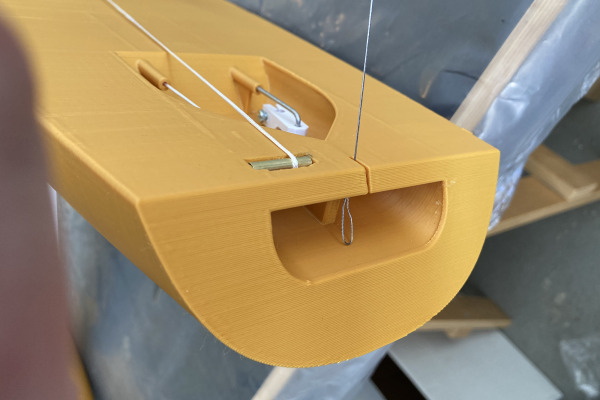

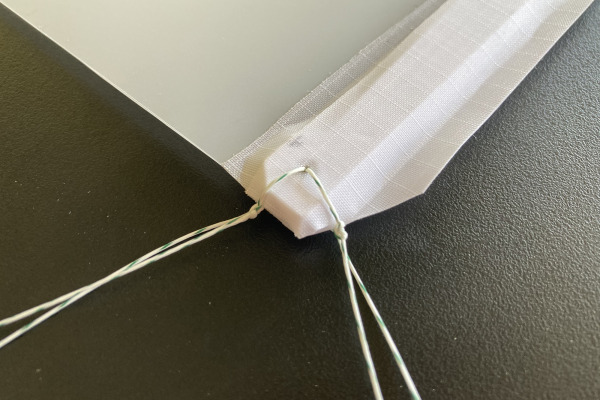

- Twist hatch for waterproofing

- Bulb shell in 2 parts, filled with lead shot

- Keel in 2 parts, with carbon reinforcement slots

- Uses standard servos for 2-channel RC

- Print Volume: 210 x 210 x 245mm (xyz)

- STLs: $26 USD Instant digital download

3D Printed Parts

To print the parts for the RS1000-3D a printer volume of 210 x 210 x 245mm (xyz) is required.

All parts are oriented correctly for immediate printing. No supports are required when printing. The design has been carefully configured to make the printing of this boat really easy.

The boat will use around 2-rolls of filament although you may want to have different colours for some parts.

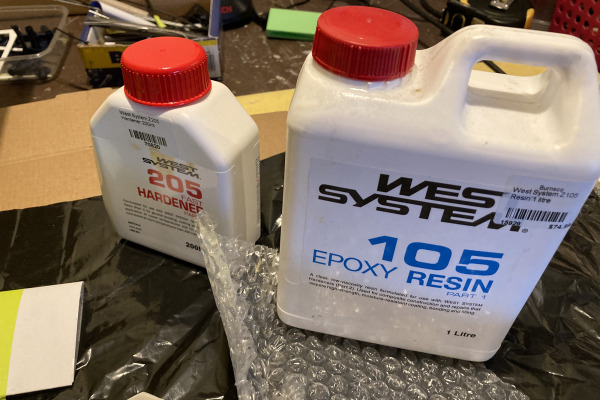

The keel, bulb and rudder are all printed parts. They have internal carbon spars to add the required strength. They are all incredibly strong once epoxied together, the end result is a rock solid boat. Many prototypes were designed/built and tested to make sure the strength was just right, not too little, not too much.

RS1000-3D Materials

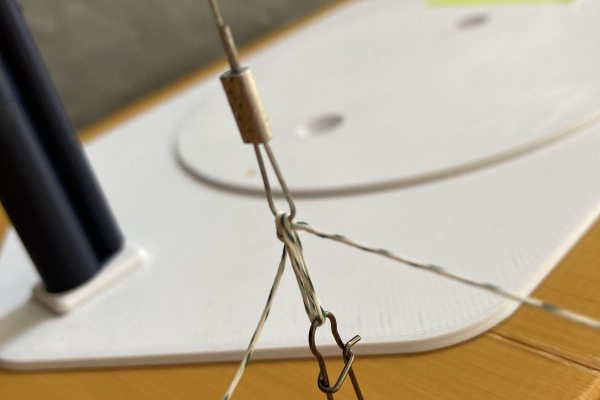

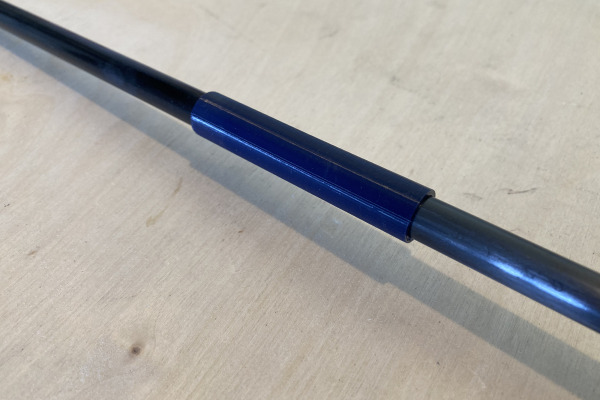

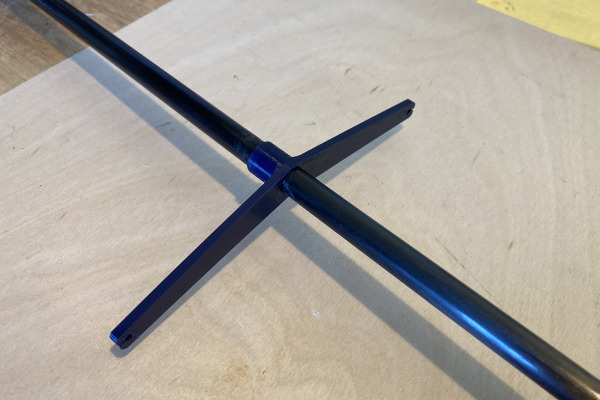

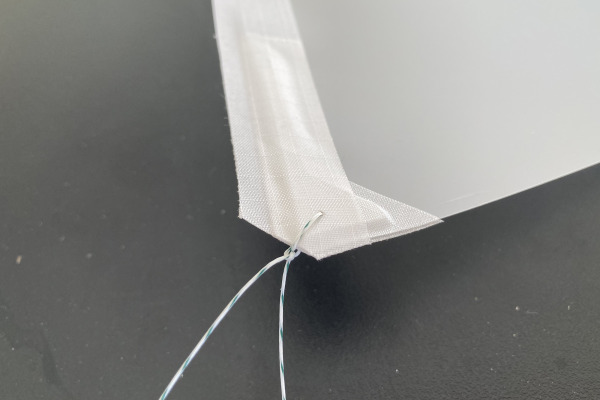

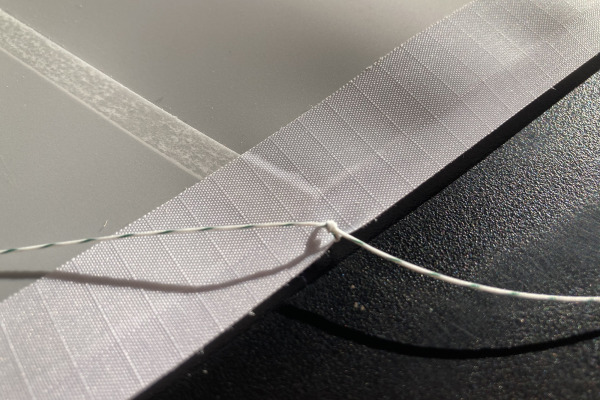

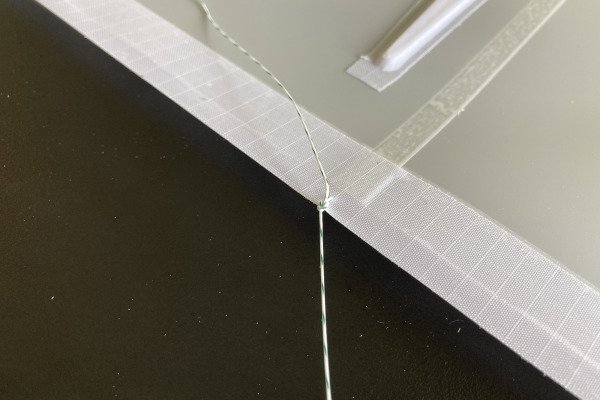

You will need a variety of carbon tubes and rods. They are super strong, cheap and readily available. Also carbon is very easy to cut and glue. Works very well with printed plastics.

The mast is 10mm carbon tube joined with printed parts.

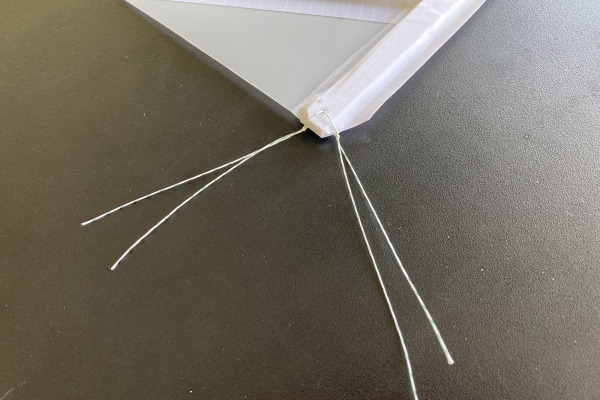

The sails can be made from many materials. We suggest architectural drafting film or reflective silver grow film.

The focus when designing this boat was readily available non specialist parts to keep costs down. A core value at Racing Sparrow Model Yachts.

RS1000-3D Electrics

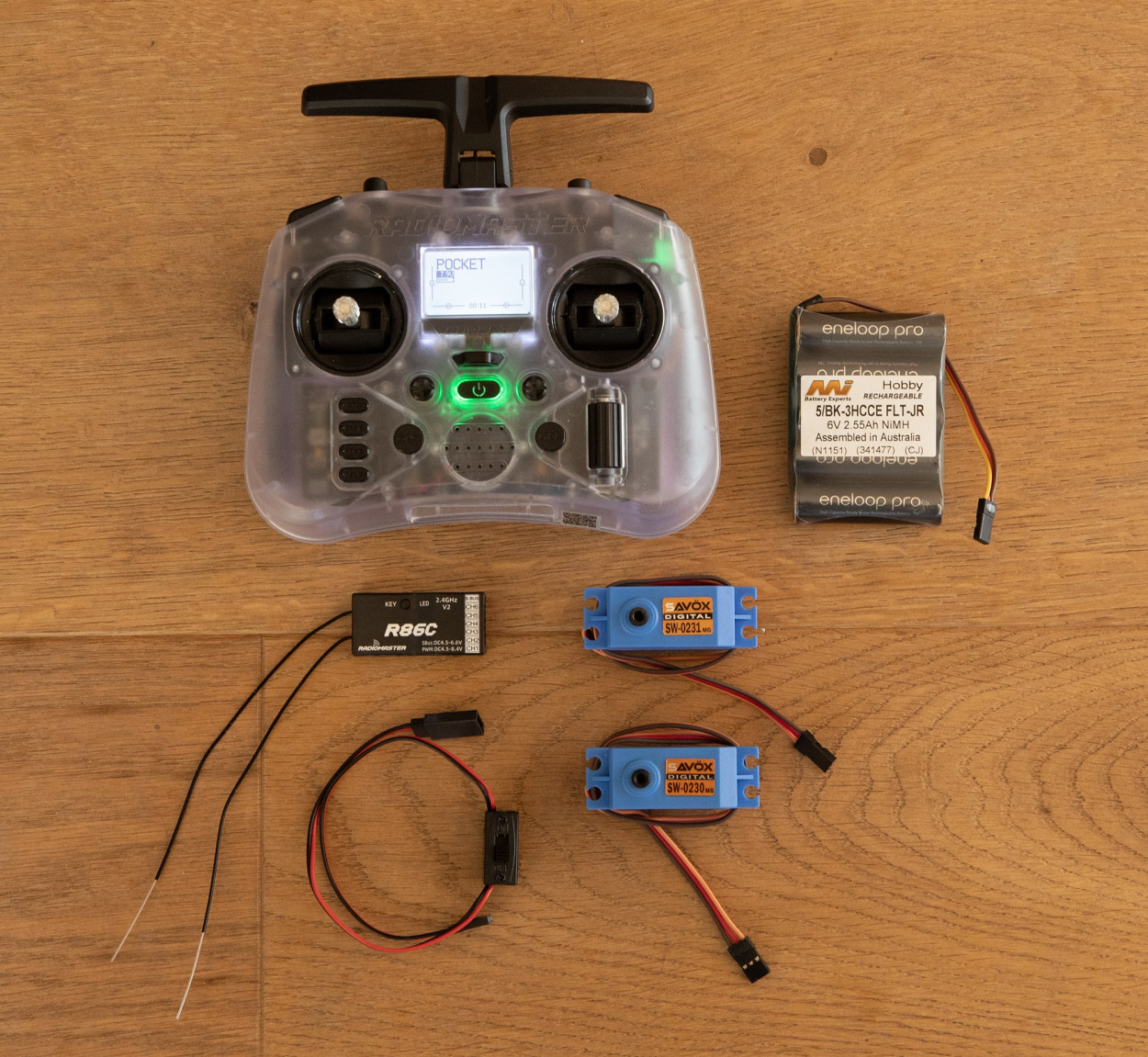

Here at RacingSparrow we use Radiomaster controller/transmitters and receivers. They are excellent value and fully featured. We are not sponsored by them, we just really like their products!

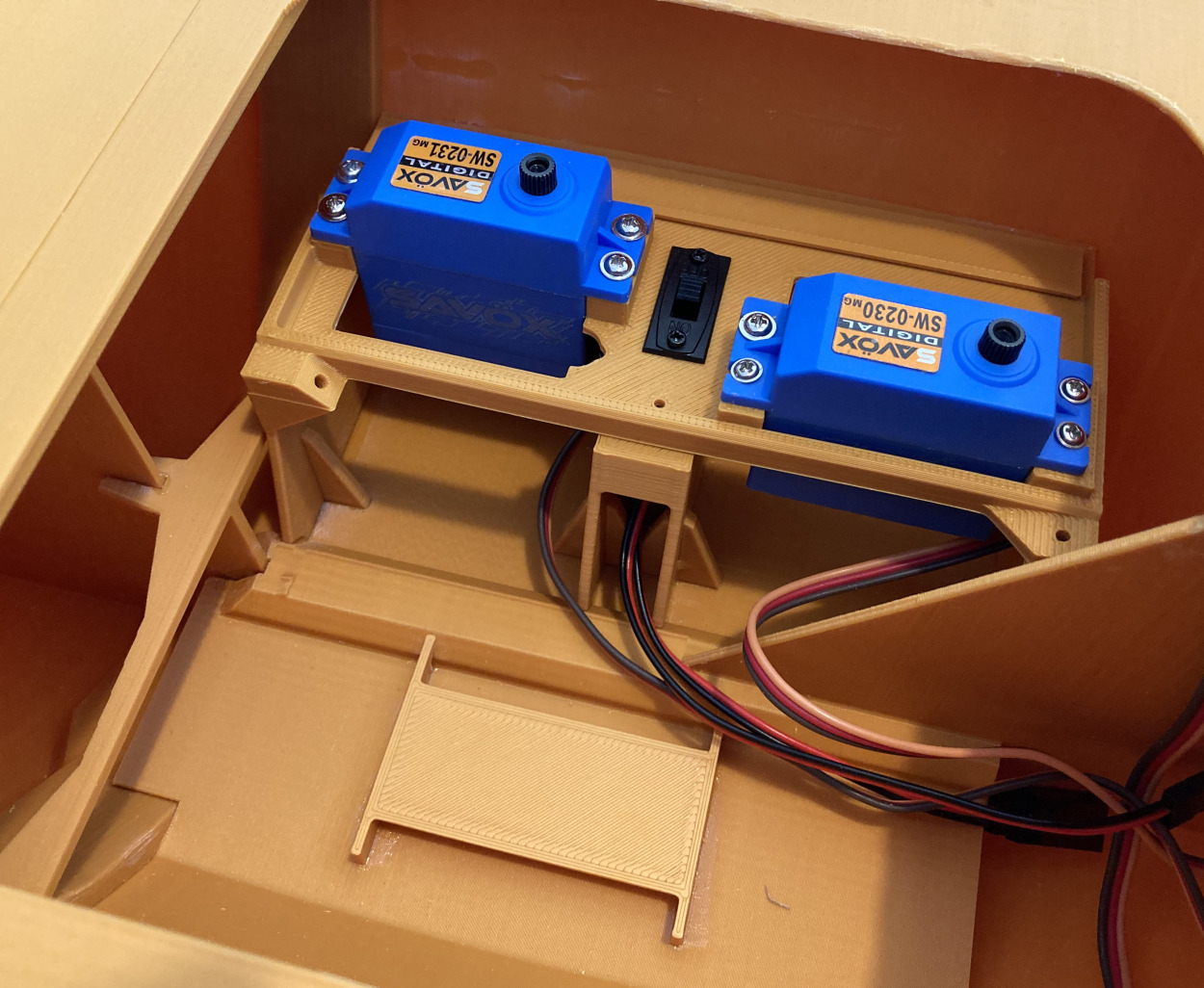

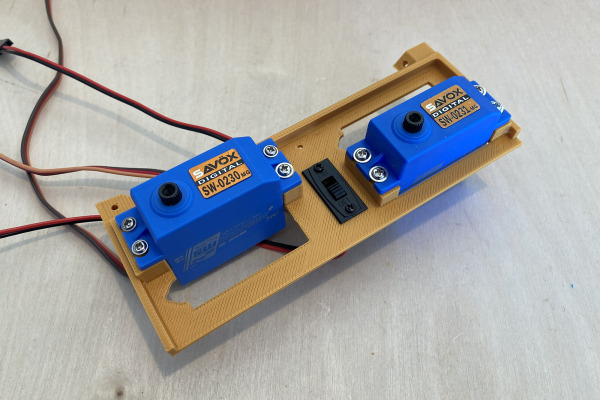

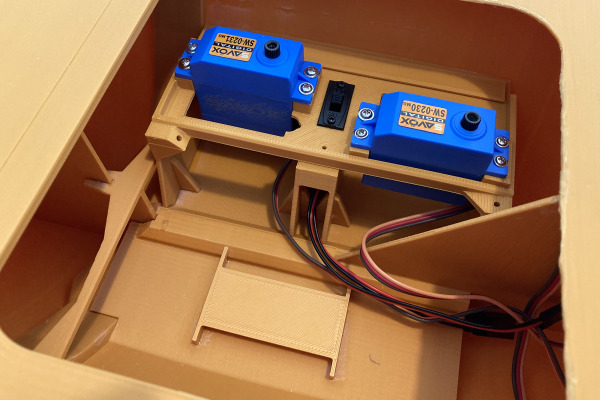

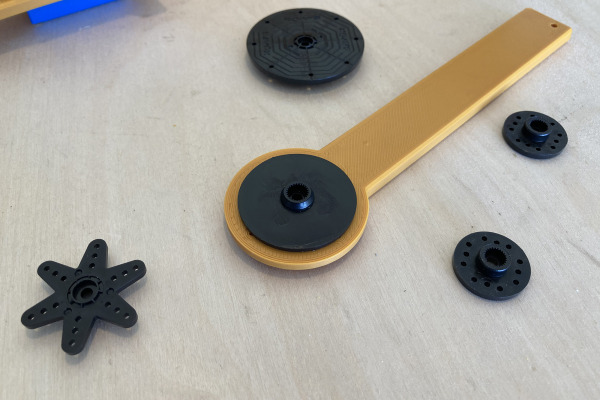

Both servos are standard size servos. The sail is controlled by a long arm attached to the sail servo. This is cheaper than using a drum winch. The image showing the blue servos shows two savox waterproof servos. A 0230 for the rudder and a stronger 0231 for the sail arm. These are premium servos for this boat. You can use any standard size servo, they don't need to be waterproof as the boat is very dry and watertight. We find the only time water gets inside is at the end of sailing when you pop the hatch and the sails shake water.

The battery box is designed for a 5AA inline battery pack @ 6V for extra power.

The On/off switch means you can set the boat up for sailing, then simply turn it on, twist the hatch shut and go sailing. All electrics are housed in a splash proof box inside the water tight hatch. Clean and simple.

Servo Placement

Both servos are standard size servos with plenty of space for longer servos if required.

The servos and on/off switch sit on the servo plate which is removal for servicing by removing the 3 screws.

Ideally a 15Kg sail servo but you can just use a cheaper one if that is preferred.

Note all electrics including the batteries are central in the boat to keep all the weight together in the middle. This helps the boat turn better and reduces pitching in waves.