Jeff Fletcher from Bastrop, TX reports

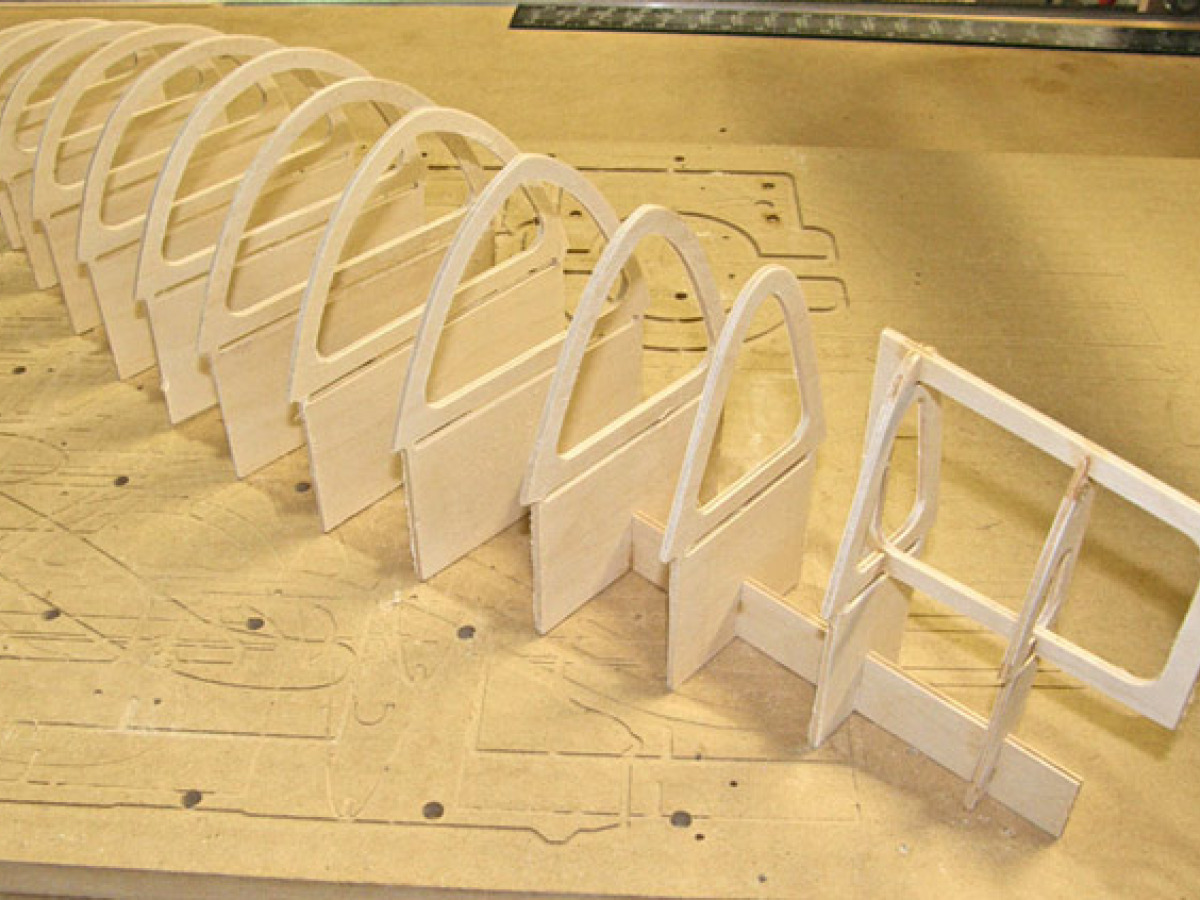

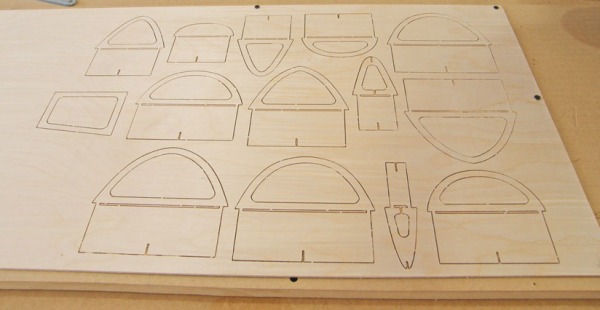

Here are some pics of the frames I made with my CNC router. I used a 1/16" bit. Guys at the local pond loved the parts. They thought they were better than laser cut parts they've seen because there is no charring on the edges.

Hello Bryn,

Here are some pics of the frames I made with my CNC router. I used a 1/16" bit. Guys at the local pond loved the parts. They thought they were better than laser cut parts they've seen because there is no charring on the edges to sand off to ensure glue adhesion. The second picture is of the frames we assembled at a local regatta to help spur interest in the RG65.

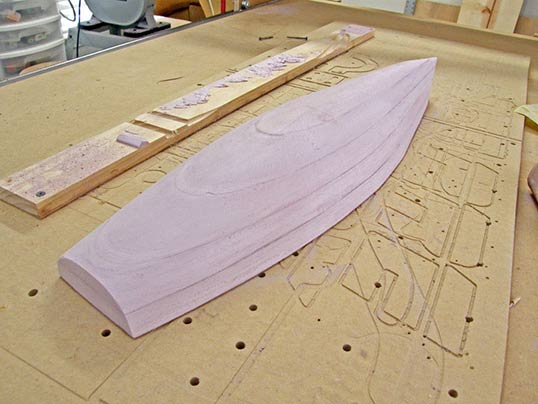

And lastly, here is a foam hull plug made from the 3-d model.

A previous email read:

Just got started helping out some local sailors with building your boat. I recently built myself a CNC router to do some other woodworking projects, but also get excited when I realized how much work I could save myself with R/C and full scale sailboats, of which I have made several. Was going to make a Star 45, but the guys here turned me on to your website so off we go.

We are wanting to build the RG65 version of the RS750. I downloaded both the PDF plans for the RG65, and the dxf file for the standard boat. I am using Rhino 3D, which allowed me to generate some beautiful hull shapes from your original. Our desire is to use my CNC router to make a plug, to crank out a bunch of hulls for some club racing.

I was wondering if you have a dxf format file available of either the RG65 frames (preferred , that are in the PDF document, or of the entire hull? I like the design changes you made to the RS750 and would like to accurately generate them in a CAD generated hull. Basically, it would save me from having to manually trace the modified sections into my CAD program. Not impossible, but I thought you might have them available already.

Thanks for your help!

Jeff

Bastrop, TX.